Theories on M3 microstructure control and the technology of high performance steels

① Background, purpose, and significance of landmark achievements

The development of steel for engineering structures is towards the direction of high-rise building facilities, large-scale engineering equipment, seismic and fire-resistant safety, and material reduction economy. The development of high-performance structural steel products that combine high strength, high plasticity, high toughness, low yield ratio, and good welding performance has become a hot topic of concern for people. The Marine Engineering Steel Team has pioneered and innovated in the research and development of new generation high-performance steel materials. We have developed the principle of "multiphase structure-metastable austenite- multi-scale precipitation" (M3) microstructure control technology, and successfully developed the third generation low alloy steel materials with high toughness and plasticity, low yield ratio, and excellent welding performance in the 500-1000MPa range.

② Key technologies

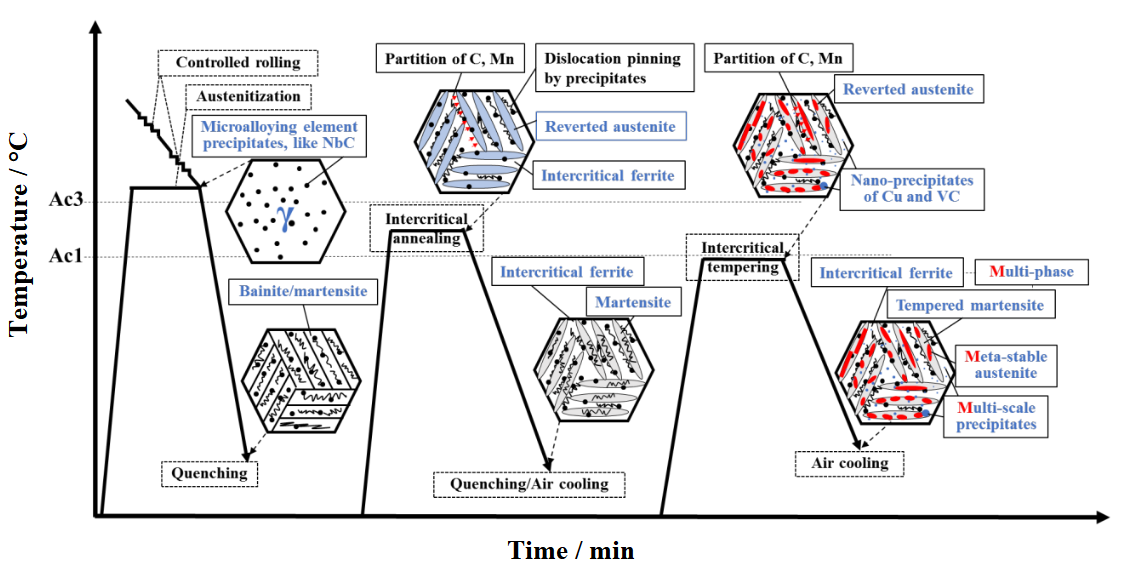

(a) Invented the "multiphase structure-metastable austenite-multi-scale precipitation" (M3) microstructure control technology, and achieved a synergistic mechanism of austenite reverse phase transformation, alloy element enrichment, and nano precipitation in multi-step heat treatment, resulting in a M3 structure with high strength, high toughness, and low yield ratio.

Figure 1. Multiphase Structure - Metastable Austenite - Multi-scale Precipitation (M3) Structure Control Technology

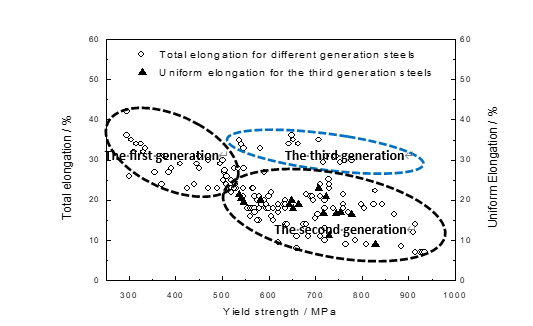

(b) Developed the third-generation low alloy steel technology with high toughness, low yield ratio, and excellent welding performance in the 500-1000MPa range, and developed high-performance steel with a uniform elongation rate greater than 10% and a total elongation rate of 20-30% in the 500-1000MPa range.

Figure 2. Yield strength and elongation of the third generation high performance steel

③ Project effectiveness and achievements

In order to break the international monopoly of countries such as South Korea and Japan on ultra-thick anti cracking steel for ultra large container ships, using the M3 microstructure control principle, we successfully developed EH40/EH47 high-performance multiphase anti cracking steel with a maximum thickness of 90mm in cooperation with Ansteel, becoming the first ultra-thick anti cracking steel product in China to obtain certification from the classification society, breaking the monopoly position abroad. Received the second prize of the Liaoning Provincial Science and Technology Progress Award and the second prize of the Metallurgical Science and Technology Award.

④ Expectations for future applications

The M3 microstructure control technology is the theoretical foundation for the research and development of high-performance steel, and will provide theoretical guidance for the production, promotion, and application of various thickness specifications of high-performance steel in China.