Team introduction

The Marine Engineering Steel Research Team (Research Institute) is based on national major engineering projects, with a focus on solving the scientific problems of urgently needed materials for high-end marine engineering equipment. It conducts systematic research on high-performance steel materials applied to offshore platforms, offshore facilities, cross sea bridges, submarine pipelines, polar facilities, special ships, and other aspects, including related design theories, key preparation technologies, and engineering applications. For many years, we have undertaken national major basic research and development projects (973), high-tech development projects (863), national science and technology support projects, national key research and development plan projects, and natural science foundation projects. At the same time, we have conducted long-term and sustained cooperative research with well-known and large enterprises both domestically and internationally, including Royal Dutch Shell, Brazilian CBMM, as well as major domestic steel and user enterprises. Significant scientific research achievements have been made in the fields of steel for offshore platforms, special ships, high-strength atmospheric corrosion resistant bridge, marine atmospheric corrosion resistance, expansion sleeves used for offshore oil development, ultra-high strength oil well pipes, oil and gas transmission pipeline, seismic, fire-resistant and weather resistant building structures, and high-performance damping alloys. Relevant achievements have been awarded at the national, provincial, and ministerial levels multiple times.

In the future, Marine Steel Research Institute will continue to conduct in-depth research and application of steel materials for ocean engineering, continuously innovate theories, methods, and products, and make greater contributions to the sustainable development of the country's blue industry and the strategy of building a strong maritime country.

Research direction

1. Material design theory, multiphase control, and high-performance variety development

2. Digital characterization and performance analysis technology for microstructure

3. Material database construction, deep data mining, and digital twin technology

4. Basic research on the application of new functional alloy materials

Research Projects

National Program on Key Basic Research Project (973 Program):

· Study of Fine Structure of the Third Generation High Strength, High Toughness and Low Alloy Steel (2010CB630801), 2010-2014;

· Study of coastal atmospheric corrosion behavior of high strength-toughness ultra-fine complex microstructure steel (2004CB619102) 2004-2009;

National High-Tech R&D Program (863 Program):

· Control of microstructure and properties of high strength and marine corrosion resistant steel and applications (2006AA03Z507), 2006-2010

· Research on 690MPa Grade Ultra High Strength Weldable Structural Steel for Marine Platform (2008AA03Z501), 2009-2010

National Key Technology Research and Development Program

· Development of High Performance Expandable Tube and its Industrialization (2015BAE03B02), 2015-2017

National Key R&D Plan:

· Seismic, corrosion-resistant, and fire-resistant steel for building structures

· 690MPa grade bridge steel with low yield ratio

· New generation of bainite track steel with low-temperature resistant, corrosion-resistant, high strength and toughness

· High strength pipeline steel under low temperature and high pressure service conditions (2017YBB0304900)

National Natural Science Foundation of China:

· Study on the Toughening Mechanism of δ-Ferrite Steel with Low density used for marine engineering

· Atomic scale study on the effect of alloy element segregation on the hardenability and low-temperature toughness of steel

· Visualization of Welding Structure and Toughening Mechanism of Ultra High Strength Marine Engineering Steel

· The Effect of Rust Layer Damage on the Atmospheric Corrosion Behavior of Low Alloy Weathering Steel

Enterprise cooperation projects:

· Baosteel: Research on the Strengthening and Toughening Mechanism of Ultra High Strength Steel Plate and Its Relationship with Substructure

· Ansteel: Evaluation of Homogenization Degree and Performance Relationship of Bainite Steel Rail

· CITIC: Study on the Behavior of Nb in J444E Ferritic Stainless Steel

· Baotou Steel: Research and Development of a New Generation of Fine Grain and Ultrafine Grain Long Profile Special Steel with High Strength and High Toughness

Teaching staff

The team consists of 2 professors, 3 associate professor and 3 visiting professors.

Xuemin Wang Shanwu Yang Hui Guo

Xiucheng Li Xuelin Wang

Academic Achievements

【 Published Paper 】 【 Authorized Patent 】 (see the personal homepage of each teacher)

Honorary Awards

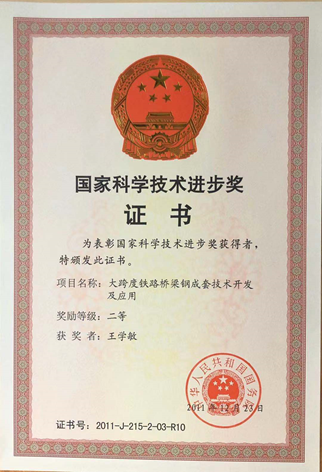

1. Second Prize of National Science and Technology Progress Award, 2011

2. Second Prize of National Science and Technology Progress Award, 2009

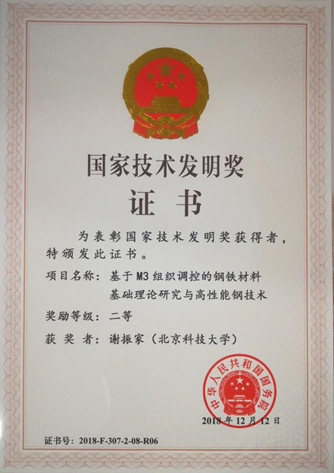

3. Second Prize of National Technical Invention Award, 2018

4. Second Prize for Invention in Beijing, 2021

5. First Prize in Metallurgical Technology, 2010

Some certificates are shown in the following figures:

Research conditions

Since the establishment of the research institute, the instruments and equipment have become increasingly abundant, and the experimental conditions have continuously improved, creating a good environment for the smooth progress of projects and the improvement of scientific research level. At present, the laboratory independently owns scanning electron microscopy (SEM), electron backscatter diffraction (EBSD) and analysis system, metallographic microscope (OM) and other microstructure characterization equipment, Vickers hardness tester, pendulum impact tester, electrochemical comprehensive experimental station and other performance testing instruments, as well as processing and sample preparation equipment such as wire cutting, sawing machine, grinding machine, box resistance furnace, and automatic metallographic sample polishing machine. The existing experimental equipment has good movement and high utilization rate.

In addition, the research institute, based in Yangjiang Advanced Alloys Laboratory, Guangdong Province, has many advanced instruments and equipment that can meet the comprehensive needs of material microstructure characterization, performance testing, corrosion evaluation, etc., such as high-resolution transmission electron microscopy (STEM), focused ion beam electron microscopy (FIB), Gleeble3800 thermodynamic simulation testing machine, ONH analyzer, direct reading spectrometer, quenching thermal expansion instrument, room temperature/high temperature tensile testing machine, instrumented Charpy impact machine, immersion corrosion testing chamber, salt spray corrosion testing chamber, fully automatic micro Rockwell/Vickers/Brinell hardness tester, various resistance furnaces, etc.

STEM SEM-EBSD

Student Training

Our research institute focuses on student development and talent cultivation. After freshmen enter the laboratory, senior brothers and sisters actively assist in learning scientific research professional skills such as the operation and use of instruments and equipment, data analysis and processing. The research atmosphere in the laboratory is warm and the living atmosphere is harmonious. The teachers are amiable and knowledgeable, willing to answer questions and concerns students' physical and mental health. We help each other and have a pleasant time together. Our senior brothers and sisters provide serious guidance, and our group is united and friendly, with a good and comfortable team atmosphere.

On the basis of standardizing laboratory management methods and regulations on the use of instruments and equipment, our research institute has established a multi-dimensional subsidy and reward system. In addition to national subsidies, the laboratory provides monthly basic subsidies, work performance subsidies, and labor subsidies. Each semester, a laboratory scholarship of 3000 RMB is selected based on scientific research performance, with excellent treatment that can meet daily expenses during the graduate period.

Our research institute provides a good development platform. After three or four years of project training and comprehensive training, master's and doctoral students have won multiple domestic and international honorary titles during their time in school, such as Dr. Miao Chengliang receiving the Charls-Hachette Award from IOM3 in the UK. And they can obtain satisfactory job positions with excellent comprehensive qualities upon graduation. In the past three years, the main destinations for graduates have been: doctoral graduates tend to choose well-known universities or research institutions for scientific research work, such as Shanghai Jiao Tong University, China University of Petroleum, Harbin Engineering University, Central Iron & Steel Research Institute, Institute of Mechanics of the Chinese Academy of Sciences, Beijing Research Institute of Ansteel, etc. In addition to continuing their studies, some master's graduates choose traditional steel companies such as Baosteel and TISCO, some choose traditional car companies such as FAW and General Motors, or new energy car companies such as Xiaopeng and Leading Ideal, while others enter semiconductor industries such as NAURA, Dawning Information Industry Co., Ltd., and Changxin Memory Technologies, with abundant employment opportunities and promising job prospects.