Design and development of high strength bridge steels

① Background, purpose, and significance of landmark achievements

At present, the strength of bridge steel in China is mostly below 500MPa. Improving its strength level and corresponding service performance will bring great cost reduction and energy conservation to infrastructure construction, while also promoting environmental protection and sustainable development of the bridge industry. Firstly, our team collaborated with Wuhan Iron and Steel Group to systematically study the effect of Nb/B on the formation of acicular ferrite, and successfully applied it to the development of WNQ570 bridge steel. The related achievements won the second prize of the National Science and Technology Progress Award. Secondly, based on the key research and development project of the 13th Five Year Plan for bridge steel led by Wuhan Iron and Steel Group, a process technology route for manufacturing large thickness steel plates through critical quenching and tempering has been proposed, revealing the multiphase structure control mechanism of 690MPa grade bridge steel, achieving excellent strength toughness matching (-40C impact energy <120J) and low yield strength ratio (0.85), while also having excellent welding performance, and achieving demonstration application on Jianghan Seventh Bridge.

② Key technologies

(a) Acicular ferrite control technology: Adding Nb and B to steel, promoting the formation of acicular ferrite through interface segregation and carbide precipitation, improving strength and toughness.

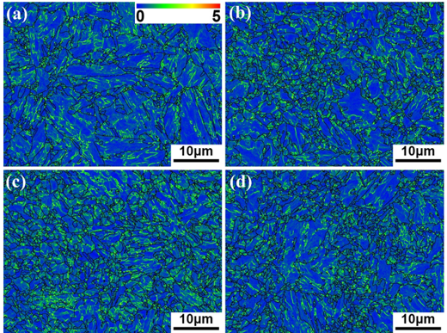

(b) Soft and hard phases control technology: Dual phase design and reducing yield ratio by adjusting the percentage and hardness of soft and hard phases.

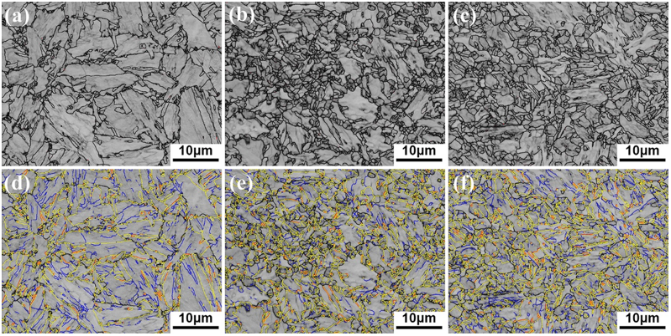

(c) Critical heat treatment technology for thick plates: By controlling the percentage and morphology of reversed austenite, the density of high angle grain boundaries is increased and toughness is improved.

Figure 1. KAM distribution maps of 690MPa bridge steel under different processes (distribution of soft and hard phases): (a) QL720, (b) QL760, (c) QL800 and (d) QLT760

Figure 2. BC maps and grain boundary distribution of 690MPa bridge steel after annealing at different critical temperatures: (a, d) QL720, (b, e) QL760 and (c, f) QL800

③ Project effectiveness and achievements

The implementation of this project has led to the research and development, promotion and application of bridge steel with high strength and low yield ratio, and the related achievements have won the second prize of the National Science and Technology Progress Award.

④ Expectations for future applications

High strength bridge steel has been promoted in enterprises and will be increasingly applied in more modern steel structure bridges. The strength level of bridge steel in China will be increased from 500MPa to 570MPa, further reaching 690MPa.