Research and development of high value-added long-life wear-resistant steel

Steel due to wear and tear caused by the consumption of about 10% of the total steel, in the "double carbon" background, facing the mining machinery for lightweight, scraper transport and agricultural machinery for corrosion resistance, mixing tank and other long life needs, in the national 863 "high-performance wear-resistant steel" program and a number of domestic steel enterprises with the support of Put forward the material design concept of series wear-resistant steel to meet different service environments, broke through the key common technologies such as high strength and toughness, easy welding, corrosion resistance, low stress, etc., developed high-performance green steel products with higher wear resistance and longer life, and were widely used in New Mining Group, China Coal Tensioning Machine, Yankuang and other fully mechanized coal mining equipment manufacturing companies. As well as Sany Heavy Industry, Shantui Shares and other construction machinery manufacturing enterprises, to achieve the iterative upgrading of wear-resistant steel materials, which is of great significance to reduce the economic loss and waste of resources caused by wear.

Key technologies: 1) Based on the micro-alloying composition design of Nb, Ti and Mo, the structure control technology of high strength, toughness and easy weldable wear-resistant steel with low Pcm value was developed, and the non-preheating welding of NM400 steel was realized in the heat input range of 16-20kJ/cm. 2) Put forward the design concept of C, Mn plus Cu, Ni alloy, the use of quenching high homogenization low temperature tempering process, to obtain the production and application of high corrosion resistance wear-resistant steel with small and micro area potential difference. 3) Based on TRIP effect, TiC particle enhanced wear-resistant steel smelting, continuous casting and TMCP preparation technology were developed. 4) The preparation technology of wear-resistant steel with medium and thick specifications TMCP+DP and the control technology of short-process low-stress wear-resistant steel with thin specifications directly quenching+straightening is proposed.

Composite precipitation in weldable wear-resistant steel

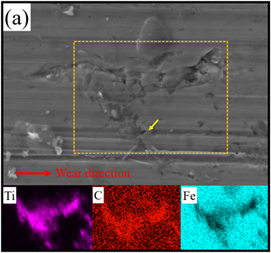

Wear morphology of particle reinforced wear-resistant steel