Digital simulation and verification of the whole process of high-end metal components

At present, the simulation of high-end metal components is mainly carried out for a single process. Most of the structural evolution is predicted by phenomenological model, which is difficult to predict accurately including complex grain morphology evolution process. In order to make the research and development process of high-end metal components iterative and upgradable, the research group deeply integrated and integrated material science calculation and machine learning models, material basic data and industrial big data, established a digital integrated research and development platform between material composition, process, microstructure and performance, promoted the original innovation of high-end metal component research and development, and improved the stability of existing product quality. Shorten the cycle of research and development, verification and production and application of high-end metal materials.

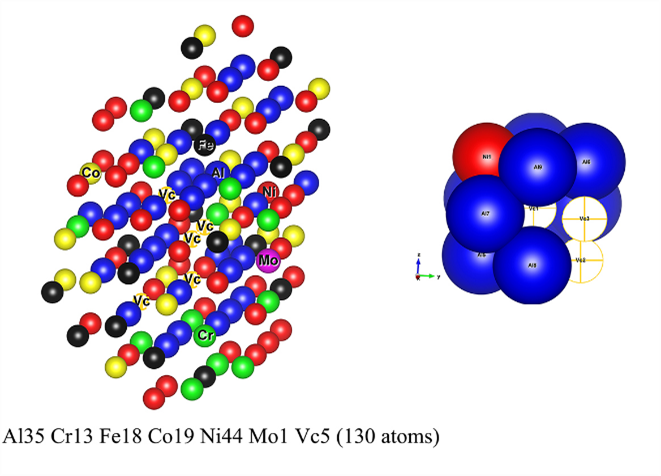

Key technologies :1) solute atomic cluster composition design and thermal/kinetic data integration technology based on computational materials science; 2) Solute atomic cluster strengthening and toughening control technology coupled with multi-scale microstructure.

Kinetic Monte Carlo method for predicting the stability of high-end alloys

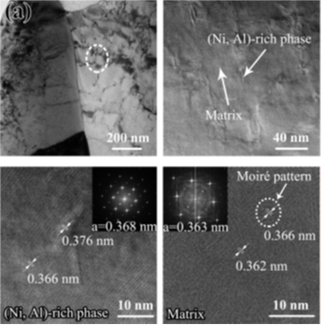

Mechanism of thermal aging of stainless steel was revealed by APT