Research and development of non-oriented electrical steel for new energy vehicles

China is the world's largest new energy vehicle drive motor manufacturing market. Driven by the market, electrical steel enterprises in Japan, South Korea and other countries have increased the research and development and production of high-grade non-oriented electrical steel. China's non-oriented silicon steel enterprises need to optimize the overall structure of the product proportion, optimize product quality and increase research and development efforts. New energy vehicles have new requirements for non-oriented electrical steel, which needs to have the characteristics of medium and high frequency, low iron loss, high magnetic induction and high strength, to meet the design and application needs of various types of motors. This requires corresponding composition and process design for different production lines to meet the needs of different applications.

Key technologies: (1) reduction ratio distribution technology of thin-gauge non-oriented electrical steel in double rolling; (2) Typical texture analysis and control technology of thin non-oriented hot rolled plate of electrical steel; (3) Influence law and parameter control technology of normalization of thin non-oriented electrical steel; (4) Special processing and preparation technology of thin non-oriented electrical steel; (5) Performance and texture control optimization technology of thin non-oriented electrical steel finished plates.

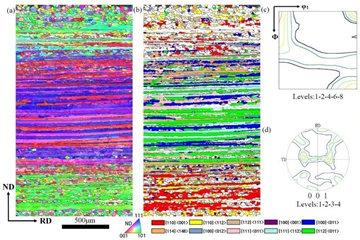

IPF diagram and typical orientation distribution diagram of RD-ND surface of hot rolled plate

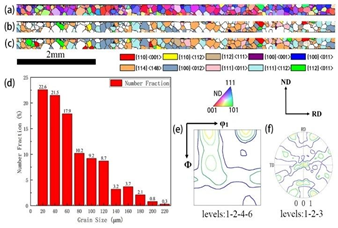

Side structure and texture of finished plate