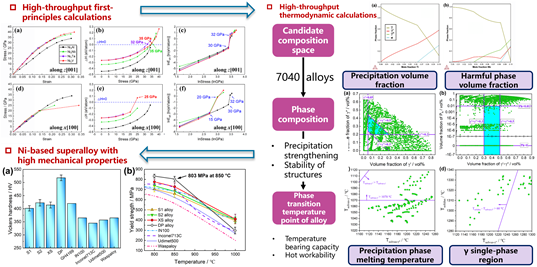

Novel Ni-based superalloys with double γ' + γ'' precipitation strengthening based on high-throughput computations and materials design

Nickel-based superalloys are key materials for high-temperature structural components of aero-engines. To improve the temperature bearing capacity of engine turbine parts, it is necessary to develop new high-strength nickel based high-temperature alloys for service at 800-850 ℃ and propose new strengthening strategies. This achievement is based on first-principles calculations, high-throughput thermodynamic calculations, and machine learning to synergistically improve the high-temperature strength, corrosion resistance, and organizational stability of nickel-based superalloys, reducing research and development time and costs. The results are of great significance for strengthening the national aviation industry, enhancing national defense technology, and accelerating the progress of national aero-engine technology.

Design of novel Ni-based superalloys with double γ' + γ'' precipitation strengthening

Based on first-principles calculations, the properties of ordered phase are investigated, and using high-throughput thermodynamic calculations for screening high-temperature alloys with γ' + γ'' precipitations. The machine learning method can improve the accuracy of extrapolation, and providing guidance for the development of new dual precipitation phase Ni-based superalloys. This achievement significantly improves the design efficiency of advanced Ni-based superalloys, and conducts in-depth research on composition, preparation process, microstructure, and mechanical properties of high-strength alloys, thereby providing a more reliable and efficient theoretical basis for practical applications. A method based on the coupling of first principles calculations, thermodynamic calculations, and machine learning is expected to improve the temperature bearing capacity of GH4169, and can contribute to the iterative updating of high-temperature alloys in national aerospace industry.