High performance automotive steel development and application

Under the increasingly stringent requirements of "energy saving, low emission, high safety and long life" and other standards, the development of high-performance automotive steel to achieve lightweight needs. The team is committed to researching and revealing the strengthening and toughening mechanism and plasticizing mechanism of high-performance automotive steel, exploring new ideas and new processes of organizational performance collaborative control, solving technical problems of batch stable production, forming and application service, realizing the research and development and application of high-performance automotive steel, and meeting the technical needs of the country in the fields of lightweight automobile, high-speed railway, transportation equipment and so on.

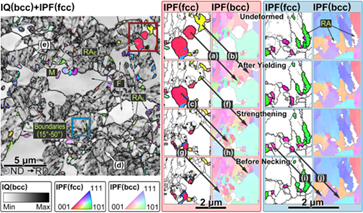

Key techniques: 1) The influence of residual austenite content and its stability on the mechanical properties of formable ultra-high strength steel was revealed, and the residual austenite with multi-scale, multi-form and different stability was obtained, which significantly improved the comprehensive properties of automotive steel; 2) The influencing factors and crack propagation mechanism of hot rolled high-form steel were clarified, and the development and application of nano-particle precipitation to strengthen high-form automotive steel was realized; 3) The main strengthening mechanism of ultra-high strength and toughness hot formed steel was expounded. The highest tensile strength of the hot formed steel developed reached 2500MPa; 4) Combined with hydrogen penetration and TDS, deuterium isotope labeling and low temperature transfer atom probe tomography were used to determine the locations of hydrogen atoms in two different matrix structures of hot formed steel, and the corresponding relationships between hydrogen atoms and dislocations, grain boundaries and precipitated phases that can be used as hydrogen traps were analyzed.

Stability of residual austenite and its mechanism of action

1) Studied the microalloying principle and enhancement plastic-strengthening mechanism of cold-rolled high-strength steel, explored the law of influence of composition and process parameters on microstructure and mechanical properties of high-strength steel, and developed HSLA steel, DP steel, CP steel and martensitic steel in cooperation with Shougang, He Steel, Ma Steel, Panzhihua Steel and Xinang Steel, based on residual austenite phase change induced plastic-strengthening mechanism. Developed QP steel, DH steel, CH steel and other series of high formability automotive steel;

2) Defined the strengthening and toughening mechanism of ultra-high strength hot-formed steel, developed 1500MPa and 2000MPa hot-formed steel, and realized industrial application, and developed 2500MPa ultra-high strength hot-formed steel through composition, structure design and process control;

3) The hydrogen-induced cracking sensitivity of DP steel, QP steel, hot-formed steel and other series of ultra-high strength steels was tested and evaluated, providing guidance for the research and development and application of hydrogen brittle steels;

4) Carried out the research and application of Nb and Ti microalloying hot rolled automobile steel based on cost and performance control, clarified the action mechanism of Nb and Ti elements, combined with the strong plastic matching and forming requirements of high-strength steel, explored the addition amount and ideal ratio of Nb and Ti elements, reduced the production cost, and met the individual needs of different users. Improve product qualification rate and market competitiveness.