Analysis and control of liquid level fluctuation characteristics of mold based on wavelet analysis

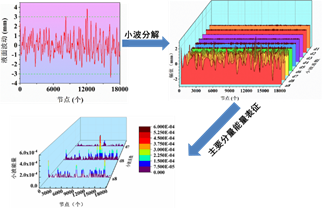

The abnormal fluctuation of the liquid level of the mold is easy to cause slag rolling, forming surface defects of hot and cold rolled plate, and affecting the uniform growth of the solidified billet shell of sub peritectic steel, resulting in longitudinal cracks and other defects on the surface of the billet. The waveform monitored by the crystallizer level meter is composed of many waves superimposed, and many details are easily ignored in the current evaluation of only the amplitude range. This technique uses wavelet analysis method to analyze the liquid level fluctuation of mold, which can be analyzed in time domain and frequency domain at the same time, distinguish abnormal fluctuation, and compare with the process parameters, clarify the formation mechanism of abnormal fluctuation, and put forward control measures, which has theoretical and practical significance.

Key technologies: 1) Optimization technology of mold flow field based on wavelet analysis; 2) Characteristic analysis technology of abnormal fluctuation of liquid level caused by submerged nozzle nodule; 3) Characteristic analysis technology of periodic liquid level fluctuation caused by peritectic steel "bulging belly"

Analysis of liquid level fluctuation characteristics of crystallizer based on wavelet analysis