Research and development of ship and offshore steels with high strength, toughness and elongation

① Background, purpose, and significance of landmark achievements

With the development of marine engineering in China towards the deep sea and ocean, the drilling depth of offshore platforms and other drilling platforms is also increasing, and marine equipment is developing towards high technology, high added value, and high reliability. Therefore, it is required that steel for marine engineering and ships be of high strength, extra thickness, and high safety. The development of high-performance shipbuilding and ocean engineering steel with a combination of high strength, high plasticity, high toughness, low yield ratio, and good welding performance has become a consensus in the steel industry. The Marine Engineering Steel Research Team collaborates with large domestic steel enterprises to develop a series of high strength and ductile plastic steel for ships and ocean engineering through research and breakthroughs in common technologies such as low yield ratio control, extreme low temperature toughness, and high plasticity. This has effectively supported the technological progress of China's marine and shipbuilding industries.

② Key technologies

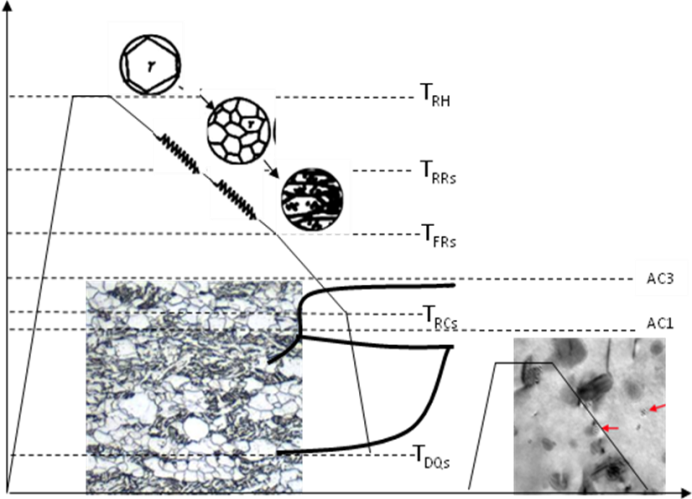

(a) By utilizing multiphase structure, retained austenite, and precipitation strengthening control, the microstructure control technology of high strength, high plasticity, high toughness, and low-temperature resistant steel for ships and marine engineering has been achieved. High strength and thick multiphase structure steel plates have been successfully developed, achieving low yield strength ratio (standard<0.85) and completing industrial production (Ansteel). They have been selected for application in Hutong Bridge.

Figure 1. Multiphase structure, retained austenite, precipitation strengthening control process

(b) Development of submerged arc welding wires used for high strength and high toughness heavy steel plate and related welding technology. Based on the understanding and in-depth research of welding metallurgy, the Mn-Ni-Mo series of high strength and high toughness submerged arc welding wires have been successfully developed, which can meet the requirements for submerged arc welding of pipeline steel with yield of 550-700MPa. They have excellent low-temperature toughness Akv (-40 ℃) ≥ 160J, Akv (-60 ℃) ≥ 125J, and some varieties Akv (-80 ℃) ≥ 105J (single value). It can meet the requirements of submerged arc welding for hot bending pipes. The weld metal has been quenched and tempered, and the low-temperature impact energy at -40 ℃ is ≥ 120J, fully meeting the performance requirements for hot bending pipes in extremely cold areas during the construction of the West East Gas Pipeline and Central Asia Pipeline.

③ Project effectiveness and achievements

We have developed a series of high-performance ship and marine engineering steels using low-carbon alloy and high strength, high toughness low-carbon bainite structure design, combined with TMCP process and tempering process (optional), in cooperation with large steel enterprises and others. The quality level has reached F level, and we have developed high strength and ductile marine engineering steels with the highest strength reaching 960MPa grade, the maximum thickness reaching 210mm, and an extremely low temperature toughness ≥ 100J at -120 ℃, as well as series marine steel welding materials with a yield strength of 550-700MPa, and -60 ℃ low-temperature impact energy ≥ 100J . The relevant achievements have won the second prize of the National Science and Technology Progress Award.

④ Expectations for future applications

In the future, we will still seek cooperation with major steel enterprises to tackle various common technical issues in application, and jointly promote various high-performance steel products for ships and ocean engineering in China to new application scenarios.