Piezoelectric Nanogenerator Based on In Situ Growth All-Inorganic CsPbBr3 Perovskite Nanocrystals in

Research background

The increase in fossil energy consumption and the resulting environmental problems require the development of renewable and clean energy sources such as solar, wind, thermal and mechanical motion. Mechanical energy in the environment is one of the most desirable alternative energy sources due to its wide distribution, diverse manifestations and easy conversion. Piezoelectric nanogenerator (PENG) is a device that uses the piezoelectric effect to convert irregular mechanical energy into electricity, and has the advantages of simple structure, small size and low influence by the external environment. It can provide power for microelectronic devices such as implantable medical devices, sensing systems, wearable electronics and portable devices, thus breaking through the limitations of traditional battery-powered problems such as large size, short service life and poor safety. Recently, the newly emerging lead halide perovskites (ABX3, A = organic group or inorganic ion, B = Pb, and X = Cl, Br or I), have received extensive attention in optoelectronic devices such as photovoltaics, photodetectors, light emitting diode, and laser diodes, due to their advantages of high photoelectric conversion efficiency, high photoluminescence quantum efficiency, superior electrical properties, tunable emission wavelength, and high color purity. Its structure is similar to the piezoelectric ceramics of lead zirconate titanate (PZT), and it is presumed to have excellent piezoelectric properties as well. However, the research on its piezoelectric properties is very limited. Meanwhile, the inherent ionic properties of lead halide perovskite make them very sensitive to heat, water and acids and bases, which greatly limits their practical application.

Article Overview

Recently, the "Green Metallurgy" team led by Professor Xinmei Hou of the University of Science and Technology Beijing Iron and Steel Generic Technology Collaborative Innovation Center has synthesized CsPbBr3@PVDF composite fibers based on one-step electrospinning methord. Based on this composite fiber, a planar piezoelectric nanogenerator was constructed, which exhibited excellent electrical output and high stability under thermal,water,acid,alkaline conditions. Related Paper “Huiying Chen, Linlin Zhou, Zhi Fang, Shuize Wang, Tao Yang,* Laipan Zhu,* Xinmei Hou,* Hailong Wang, Zhong Lin Wang, Piezoelectric Nanogenerator Based on In Situ Growth All-Inorganic CsPbBr3 Perovskite Nanocrystals in PVDF Fibers with Long-Term Stability, Advanced Functional Materials, 2021, 2011073. (DOI: 10.1002/adfm.202011073)”

Graphic guide

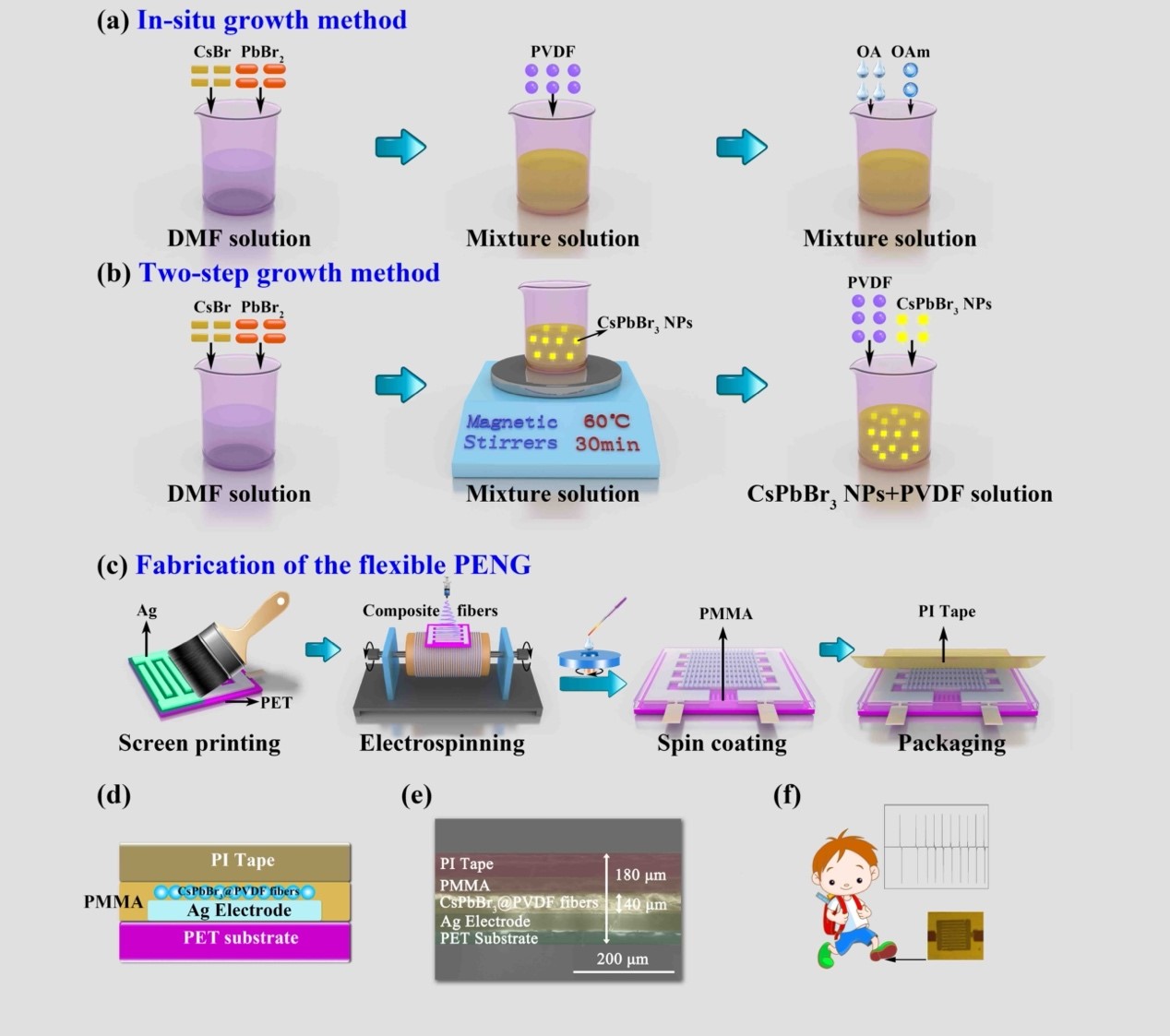

Figure 1. a) Preparation of precursor solution of CsPbBr3@PVDF for in situ growth method. b) Preparation of precursor solution of CsPbBr3@PVDF for two-step growth method. c) Schematic diagram of fabrication of the flexible PENG. d) Schematic diagram of PENG structure. e) The cross section of the PENG based on in situ growth method. f) Display of energy collection during walking.

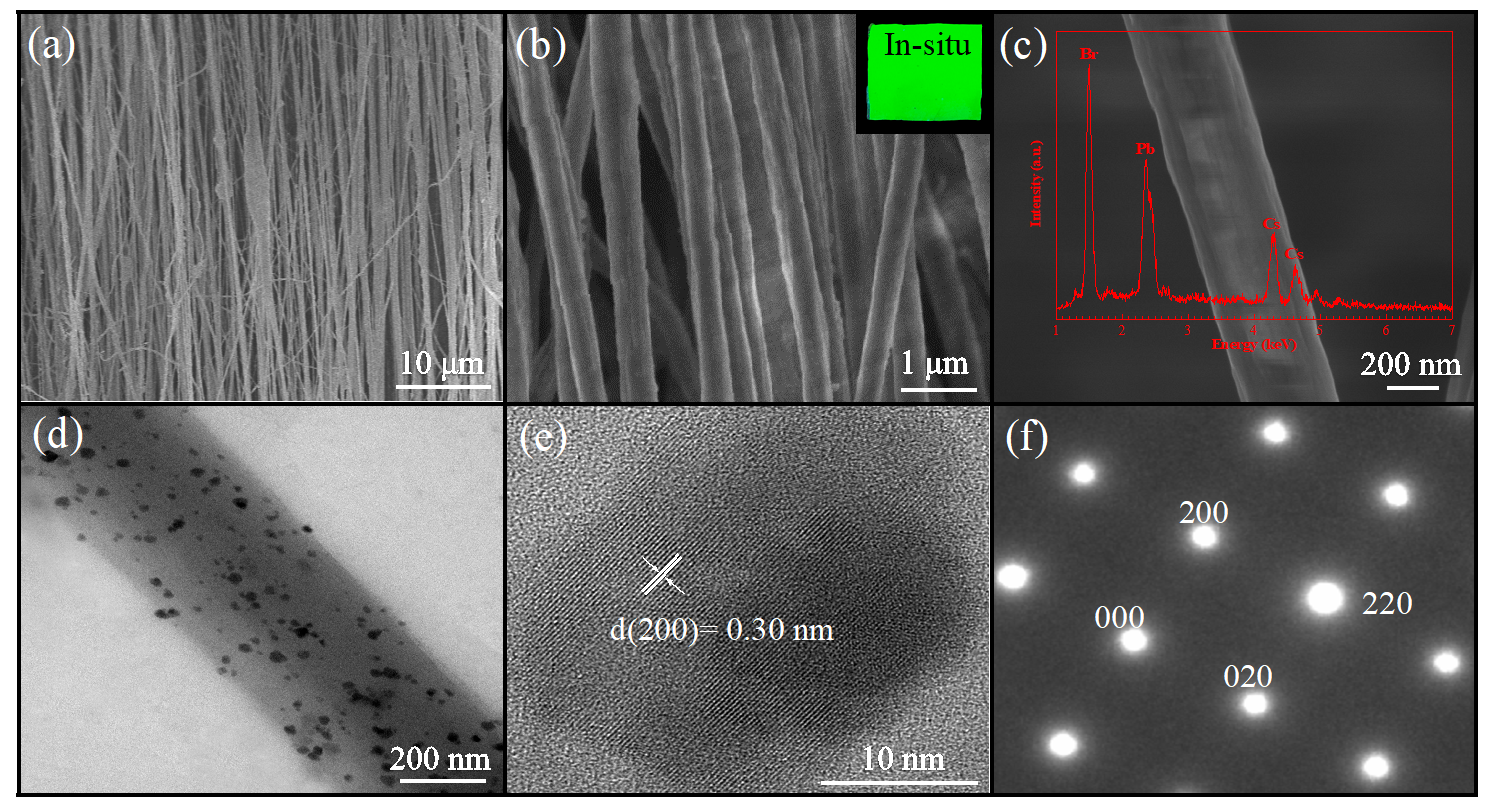

Figure 2. a–c) The SEM images of CsPbBr3@PVDF of in situ growth method, the inset of (b) is the optical image of the composite under 365 nm UV light, the inset of (c) is the EDS. d) The TEM images of CsPbBr3@PVDF of in situ growth method. e) HRTEM image of CsPbBr3 NCs. f) SAED pattern of CsPbBr3 NCs.

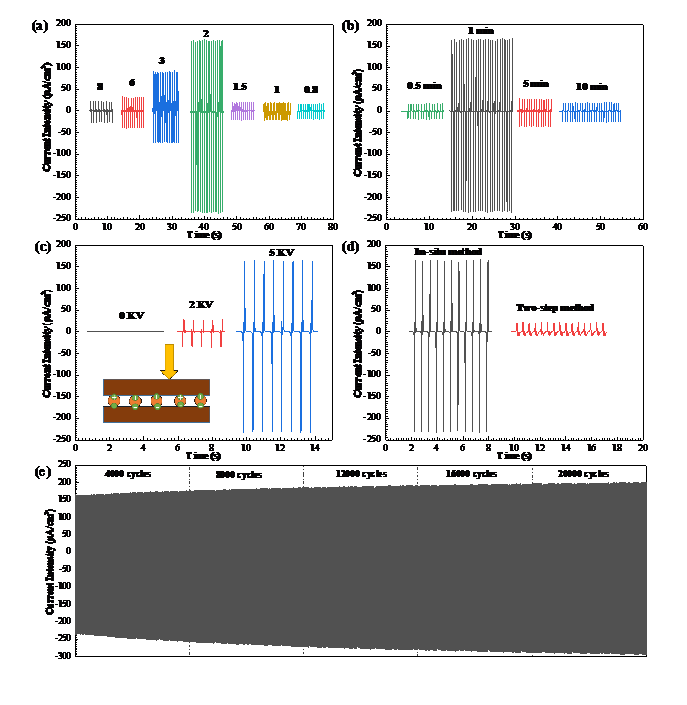

Figure 3. a) The density of Isc of PENGs with composite fibers prepared with different mass ratio of PVDF:CsPbBr3. b) The density of Isc of PENGs with different electrospinning time. c) The density of Isc of PENGs with different polarization voltages, and the inset of (c) is under potential of 15 kV to polarized and the charges are arranged in order. d) The density of Isc of PENGs with different fabrication method. e) Stability of PENG tested under a final velocity of 10 m s−1 for 20 000 cycles.

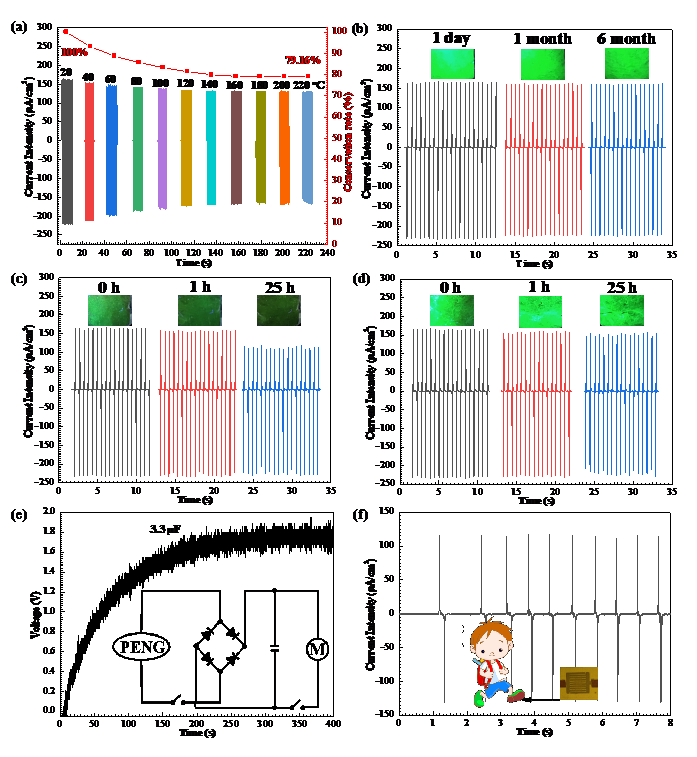

Figure 4. a) The density of Isc of the PENG at different temperature. b) The density of Isc of the PENG before and after soaking in water for different time. c) The density of Isc of the PENG before and after soaking in sulfuric acid solution for different time. d) The density of Isc of the PENG before and after soaking in sodium hydroxide solution for different time. The inset of (b–d) are the optical image of the composite under 365 nm UV light. e) Charging curves of capacitors by the PENG, the inset of (e) is rectifying circuit diagram with the PENG. f) The density of Isc of the PENG under feet walking, the inset of (f) is the schematic diagram of a man walking on a PENG.

Conclusion

Based on one-step electrospinning of solutions containing CsPbBr3 precursors and polyvinylidene difluoride (PVDF), in situ growth of CsPbBr3 nanocrystals in PVDF fibers (CsPbBr3@PVDF composite fibers) with highly uniform size and spatial distribution are synthesized. The stability was improved by completely encapsulating the less stable CsPbBr3 nanocrystals with highly stable PVDF, which completely isolated them from the environment. The stronger piezoelectric properties of CsPbBr3 nanocrystals are also utilized to improve the piezoelectric properties of the composite fibers. The CsPbBr3@PVDF composite fibers based PENG reveals an open-circuit voltage (Voc) of 103 V and a density of short-circuit current (Isc) of 170 µA cm−2, where the Voc is comparable to the state-of-the-art hybrid composite PENGs and the density of Isc is 4.86 times higher than that of lead halide perovskites counterpart ever reported. Moreover, the PENG exhibits fundamentally improved thermal/water/acid–base stabilities. Their output ability retains beyond 79.16% of its original value after being heated at 220 °C for 1 h, maintains almost 100% after being immersed in water for 6 months, retains 63.53% after being immersed in sulfuric acid solution for 25 h and maintains over 82.35% after being immersed in sodium hydroxide solution for 25 h. The PENG with a superb stability serviced under harsh environment, such as thermal, humidity, acid, and alkali, is better than the best one ever reported for hybrid composite materials PENGs. The PENG reveals emerging prospect in the realization of wearable energy collectors and self-powered electronic equipment.

Team introduction

The "Green Metallurgy" team of the University of Science and Technology Beijing Iron and Steel Generic Technology Collaborative Innovation Center is based on the theoretical basis of metallurgical physics and chemistry, breaking through the limitations of traditional metallurgy, chemical industry, energy, environment and materials, and exploring the effects of new materials in the fields of steel, energy and environment. enhancement. The main research directions of the echelon include: (1) interface reaction kinetics; (2) research on the boundary wettability of high-temperature solutions; (3) development of new high-temperature ceramic materials; (4) metallurgical process wastewater, waste liquid, flue gas and solid waste Governance and comprehensive utilization; (5) Development of new optoelectronic and power-electric functional materials and device construction, etc.; (6) Multi-structure control of functional materials based on electrochemical metallurgy. Currently, there are 3 Professors (including 1 National Distinguished Young Scholars), 1 Associate Researchers, and 1 Assistant Researcher. The team has undertaken more than 20 national, provincial and ministerial projects, published more than 200 SCI papers, applied for more than 30 patents, and won more than 10 provincial and ministerial awards.

The research group of professor Xinmei Hou

The research group of professor Zhangfu Yuan